Manual Handling Techniques & Tips

Manual handling accidents, as a result of pushing, pulling or lifting heavy objects or machinery, account for more than a third of all reported accidents each year. This short guide provides the best manual handling techniques to follow in the workplace so that you can reduce the likelihood of injury occurring.

Need Manual Handling Training?

Our Manual Handling Training Course helps employers ensure that they and their employees are sufficiently trained in the principles and practices of safe manual handling.

What is Manual Handling?

Moving and handling, also known as ‘manual handling’, is any action involving physical effort to move or support an object or person by:

- Lifting

- Pushing

- Pulling

- Manoeuvring

- Steadying

- Carrying

- Transporting

By law, employers are required to undertake a risk assessment and do everything that is reasonably practicable in order to reduce the risks associated with manual handling. Amongst other actions, this includes introducing control measures to ensure workers understand how to lift, push and pull correctly, using mechanical aids where available and reducing the need for manual handling altogether.

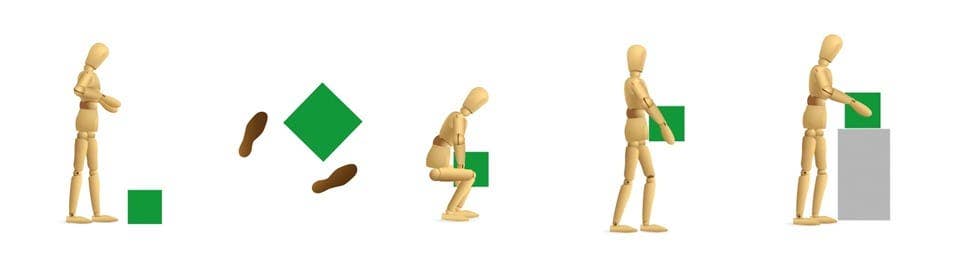

Manual Handling Techniques for Lifting

- Before lifting an item, think: Can you use a manual handling aid instead? Where is the load being moved to? Are there any obstructions that may get in the way?

- Adopt a stable position with feet apart and one leg slightly forward to maintain stability. Make sure that you are wearing suitable footwear.

- Get a good hold on the load and hug it close to your body where possible. At the start of the lift, bending at the back, knees and hips is preferable to fully bending the back or squatting.

- When carrying, keep the load close to your waist for as long as possible. Put the heaviest side of the load closest to your body. Keep your head up and look ahead, not down at the load, and avoid twisting or leaning sideways.

- If you need to, put the load down and adjust your grip before continuing the lift.

Pushing or Pulling Loads

When pushing or pulling a load, the Health and Safety Executive provides the following guidance:

- Use an aid with a handle height that is between shoulder and waist height.

- Ensure that pushing or pulling equipment is well maintained.

- As a guide, the amount of force that needs to be applied to move a load over a flat surface is at least 2% of the load weight. For example, if the load is 400kg, then the force needs to be 8kg.

- The force for pushing or pulling will be greater over imperfect conditions.

- Always try to push rather than pull where possible.

- When negotiating a slop or ramp, get help from another worker.

- On an uneven surface, increase the pushing/pulling force to 10% of the load weight.

- To make it easier to push or pull, keep your feet well away from the load and move no faster than walking speed.

What to Read Next:

- Manual Handling Weight Limits: What are the Safe Lifting Guidelines and Techniques?

- Manual Handling Training

- What Does TILE Stand For? The TILE, TILEO & LITE Acronyms

- Manual Handling Training: What are the Regulations?

- Manual Handling Quiz

- Team Manual Handling Tips

- What are the Consequences of Poor Manual Handling?

- Workplace First Aid Training