Spill Management Training

Quantity: 1

Duration 2 hours

100% online training

Start when you like

Learn on any device (desktop, mobile or tablet)

Instant assessment and result

1 learner per course

Train teams of all sizes

Bulk discounts starting at 10% off 10 courses

Pay by invoice with 30 day payment terms available (5+ courses)

This Spill Management Training course shows how to safely store, use and transport dangerous substances in order to minimise the risk of a spill. It also explains the most effective methods of spill response in the workplace and how to effectively use a Spill Kit.

This course outlines the responsibilities that employers have if their workplace and work activities involve using dangerous substances in quantities above COMAH threshold limits.

100% online training

Access anywhere

Same day digital certificate

Printed certificate posted next working day

Full audio voiceover

Assessment retakes at no extra cost

Legally accurate in line with any guidance changes that have resulted from Brexit legislation - including any revisions to deadlines

Written in compliance with UK legislation and guidance

Developed by health and safety professionals

Accredited by CPD and assured by RoSPA Qualifications

Bulk discount for orders of 10+ courses

Save on our courses when you buy more training upfront. Lock in a better price now and access the training whenever you need to. You can mix and match any of our courses too and get the discount off your whole order.

10+ courses = 10% off

50+ courses = 20% off

100+ courses = 30% off

500+ courses = 40% off

By the end of this course, you will:

Recommended renewal:

1 year

What does this mean? This certificate does not have an expiry date, however, based on industry best practice guidelines there is a recommended renewal period.

Our in-house Learning Designers develop all of our courses to give you and your learners the most engaging training possible.

What is a hazardous material, types of hazards posed by hazardous substances, why is spill prevention important, legal responsibilities, case study: Buncefield, United Kingdom, 2005, and case study: Union Carbide India Ltd, Bhopal, India, 1984.

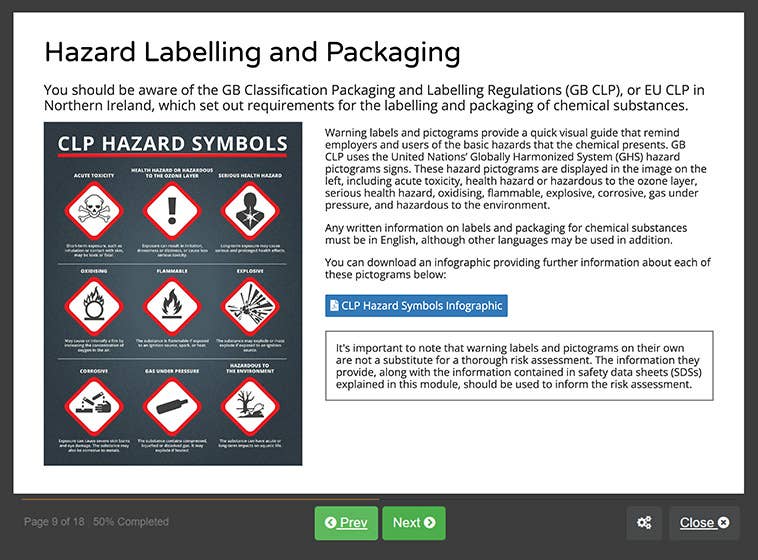

Classification, Labelling and Packaging Regulation 2008 (CLP), hazard labelling and packaging, chemical labels for transporting hazardous goods, storage of dangerous goods, before accepting a shipment of hazardous substances, safety data sheets (SDSs), accepting a shipment of hazardous substances, control measures for storing hazardous substances, using hazardous chemicals safely, and emergency procedures.

Managing a spill, planning for a spill or leak, why do spills occur?, pollution risk assessment, engineering control options, administrative controls, Pollution Incident Response Plan, and writing a Pollution Incident Response Plan.

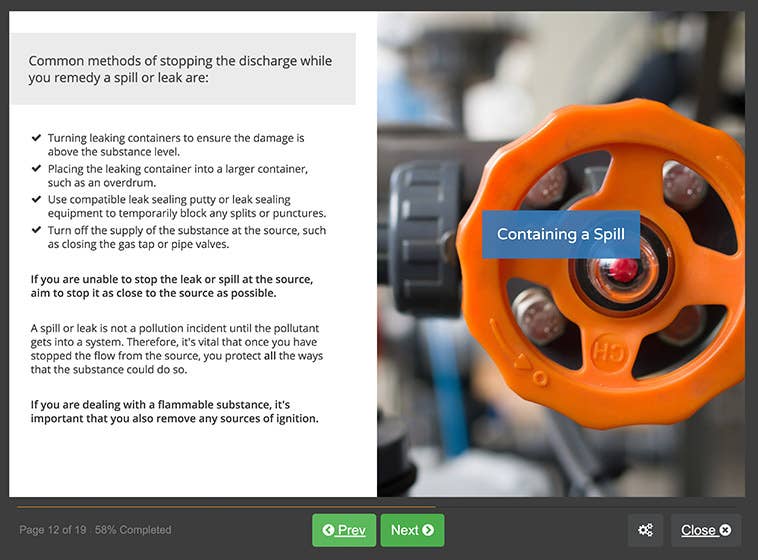

Recognising and evaluating a spill or leak, evaluating the risks, quantities and potential impacts, spill kits, vehicle spill kits and training, stopping the spill or leak at the source, containing a spill, protecting all the ways that the pollutant can get into the system, cleaning up the spill, assessing the spill and refilling your spill kit, and spill management training video.

The online assessment is taken on completion of the training material. You will be asked 15 multiple choice questions with a pass mark of 80%. The answers are marked automatically so you will instantly know whether you have passed. If you don't pass don't worry! You can take the test as many times as you need with no extra charge.

This Spill Management Training course is aimed at employees who work in industries where they are required to use, store or transport hazardous substances, such as solvents, pesticides and fuel.

The course is also beneficial for employers in these sectors. It outlines their duties and how to install controls to protect people, animals and the environment from the consequences of a spill.

In partnership with

Neil Murray

Health and Safety Consultant

Neil Murray is a vastly experienced and highly qualified health and safety professional who has held roles such as Senior Health and Safety Executive inspector, and Principal Inspector for Channel Tunnel construction. He has also held senior roles in an international infrastructure business, a major UK water utility company and a major construction group and provided management consultancy to numerous companies across a wide range of industries.

Neil has a wide expertise in many sectors, including construction, civil engineering, manufacturing engineering, water and waste utilities, education, heritage sites, public safety, rail construction and operation, transport, marine, waste management, engineering design and industrial and facilities management services.

Neil is a QSA auditor for RoSPA and also an author of published guidance on health and safety in the construction of the Channel Tunnel, work at height, major project management, and online training courses.